- Home ...

- Sustainability

- Environmental

- Stewardship

- Waste reduction

Waste reduction

Waste minimization is a core element of Eastman’s sustainability journey and long-term planning. Our strategy includes four focus areas: development of an infrastructure for waste, alignment with Eastman’s circular economy position, promoting innovative recycling methods, and education and engagement of various stakeholders with a focus on waste minimization.

Developing an infrastructure for waste

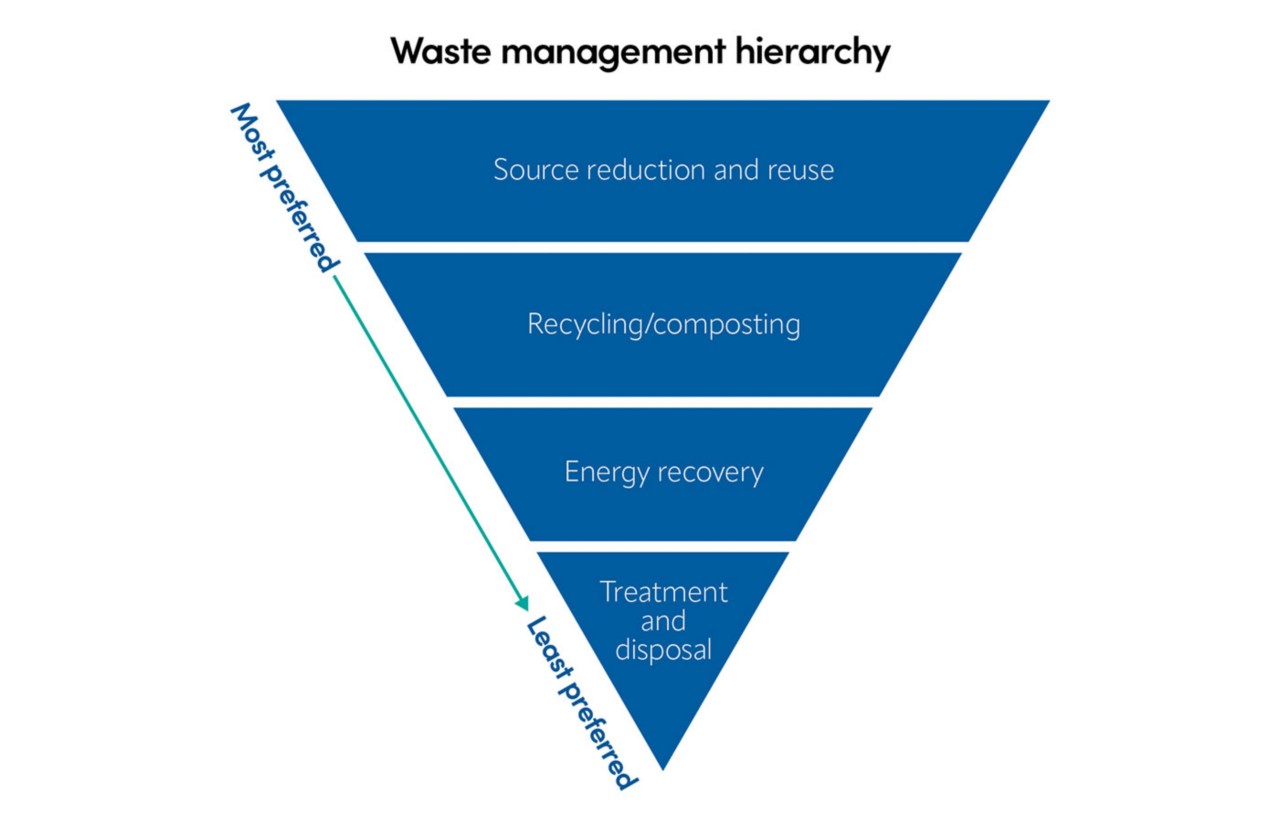

Eastman supports the waste management hierarchy. Our waste management efforts are being designed to reduce or eliminate the generation of waste whenever possible. When waste reduction/elimination is not possible, we will move down the waste management hierarchy with treatment and disposal as a last resort.

To generate a representative waste baseline, Eastman conducted a waste characterization study in 2022 in Kingsport, Tennessee, home to our largest manufacturing site. We used data from that study to identify specific waste minimization opportunities; the data will be used to set waste metrics and goals that we will report in the future. We will conduct similar characterization studies at our other manufacturing sites. Additionally, annual waste data for all Eastman sites will be used to enhance our infrastructure strategy in 2023.