Step 1: Storage

- Store Nemasol™ in closed, original packaging with the original label.

- Storage room should be cool, ventilated and kept locked.

- The maximum volumes to be stored at one site should correspond with local regulations.

- The storage area should display no-entry signs and signs indicating the presence of hazardous and corrosive materials.

- The storage room should have a basin-shaped floor to retain any spills in case of product leakage.

- The temperature should not exceed 35°C.

Step 2: Check local conditions

If necessary, the application should be postponed until conditions are more favorable.

- Localization — Check for neighboring buildings (both residential and nonresidential) and the presence of water surfaces, drainage ditches, animal husbandry and adjacent crops.

- Field condition — Check field conditions, including presence of plant debris, appropriate soil preparation (crumbled and prewetted), soil temperature and humidity.

- Greenhouse — Check for broken windows and cracked or torn plastic roof and/or walls.

- Wind and rain — Check for wind direction, and consult the wind forecast, including for the days immediately following. Do not apply metam-based products during rainy periods, thunderstorms or strong winds.

- Temperature — Consult the temperature forecast for the risk of temperature inversion. Do not apply if temperature inversion is forecasted for the 48-hour period after the start of application.

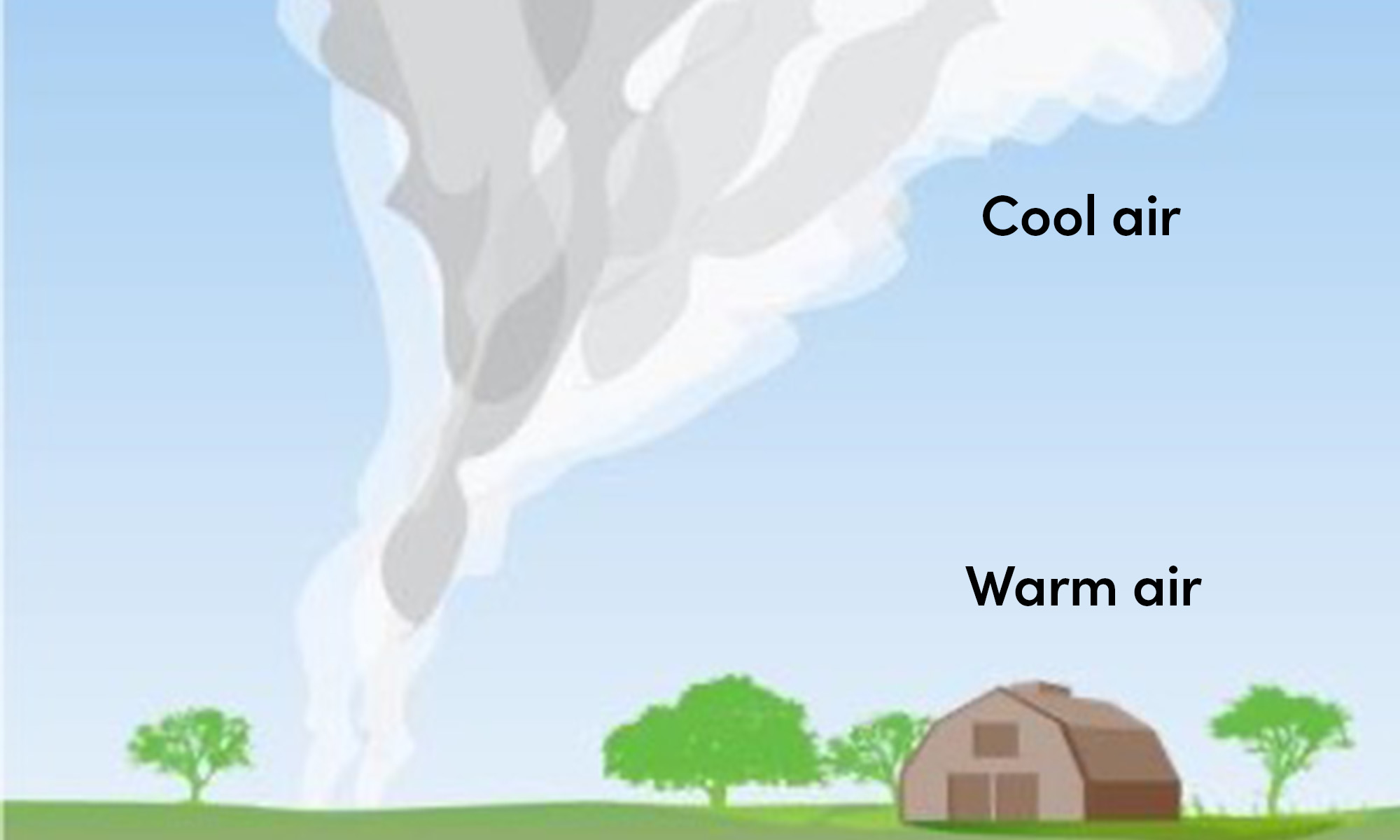

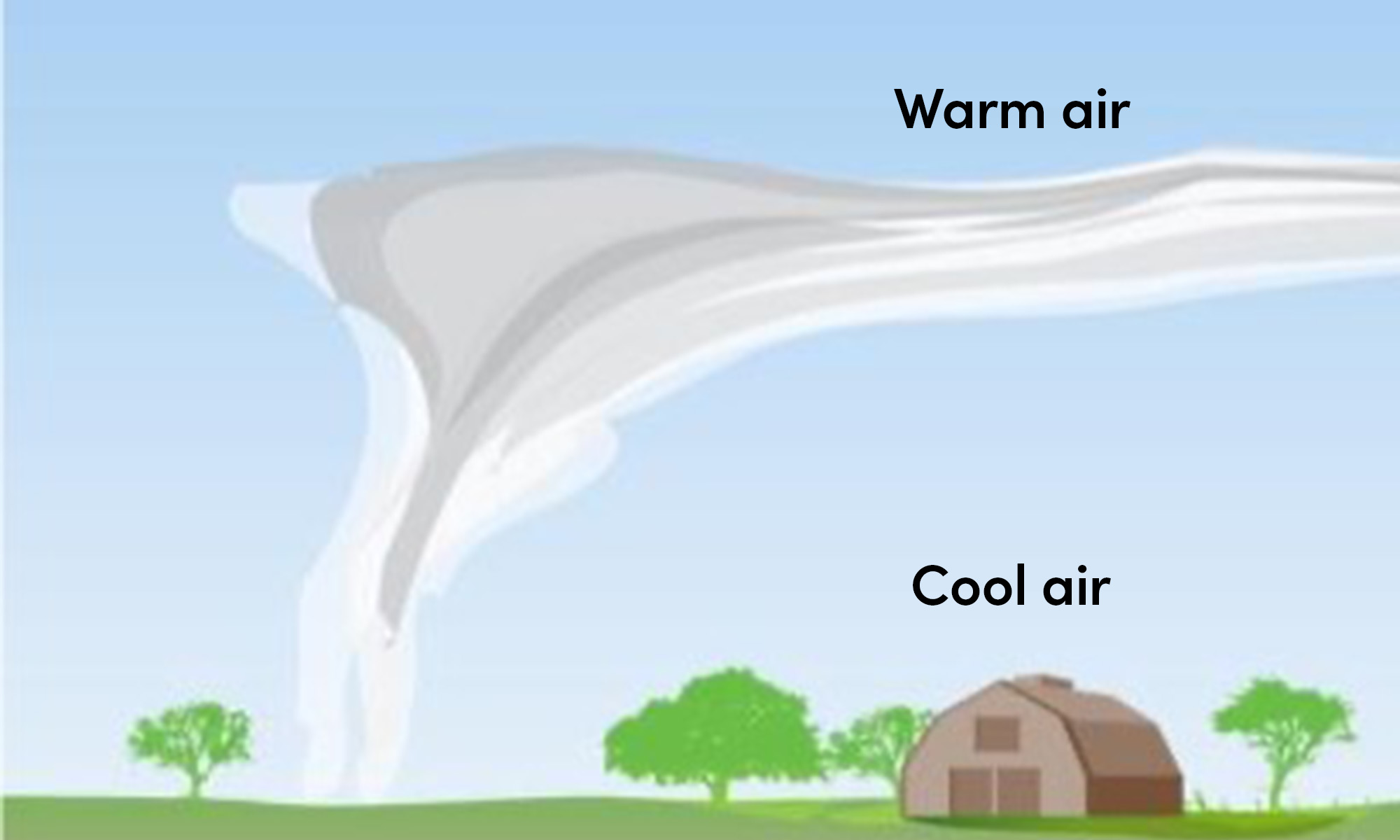

- Temperature inversion is often to blame for human exposure to disinfectants.

- During an inversion, warmer (lighter) air rises above cooler (heavier) air, causing cooler air to settle near the ground.

- Disinfectant vapors settle and concentrate near the ground.

- Clues that inversion conditions exist include:

- Ground fog or smog that remains concentrated with little upward movement.

- Smoke from the ground that slightly rises and flattens out.

- Temperature inversion conditions typically start an hour before sunset and continue past sunrise but can also persist all day long.

During a typical day, smoke rises and disperses.

With temperature inversion, smoke concentrates.

Step 3: Product application

Handling and product transfer

- Product handling is the most critical phase.

- Before starting any handling, the worker should dress in the appropriate personal protective equipment (PPE). See the PPE section of the website here.

- Nemasol transfer from drum to tank must be carried out with appropriate connections.

- Attention must be paid to compatibility of metam with other materials:

Materials compatible with metam

| ✓ High-density polyethylene (HDPE) |

| ✓ Polypropylene |

| ✓ Polyamide (Nylon 6) |

| ✓ Polytetrafluoroethylene (PTFE; Teflon) |

| ✓ Fluoroelastomer (Viton) |

| ✓ Glass fiber |

| ✓ Stainless steel |

Materials incompatible with metam

| ✗ Copper |

| ✗ Soft steel |

| ✗ Aluminum |

| ✗ Brass |

| ✗ Galvanized steel and zinc |

| ✗ Polyvinylchloride (PVC) |

| ✗ Nitrile butadiene rubber (NBR; Buna-N) |

| ✗ Ethylene propylene diene monomer rubber (EPDM) |

| ✗ Chlorosulfonated polyethylene rubber (CSM; Hypalon) |

| ✗ Neoprene |

| ✗ Butyl rubber |

| ✗ Low-density polyethylene (LDPE) |

- The transfer site must have an impermeable floor to enable collection of any product in case of spillage.

- The product must not be handled close to waterways, ditches or residences.

Warning notices/signs

- Inform residents living withing a 200-meter radius of the plots to be treated about the periods of application prior to every application campaign.

- Keep greenhouse entrance doors closed until ventilation.

- Ensure treated fields and greenhouses are indicated by no-entry warning signs displaying messages such as “No trespassing” or “Fumigation in progress.”

Product application

Soil injection/incorporation:

- Only tractors with closed cabins may be used for the mechanical incorporation of metam-based products.

- It is not advisable to use a tractor with an open cabin or no cabin.

- It is important not to bring any clothes, boots or devices soiled with metam-based product into the cabin. Always wear the appropriate PPE for any intervention on the field or the application machine.

Drip irrigation:

- Take utmost care when coupling and uncoupling the metam drum or container to and from the drip-irrigation device or pump.

- When applying the product indoors, keep greenhouses or tunnels closed until after the reentry period, when the relevant ventilation process can start. See step 4: reentry period.

Step 4: Reentry period

Due to the volatile chemical properties of metam and MITC, entry into a treated field during a certain period is restricted to handlers wearing appropriate PPE.

The reentry waiting period starts at the end of the product application. Always follow local label requirements. They can differ, depending on the application site (open field or greenhouse), climate and region.

- Open field: Depending on the regional climate, the recommendation is to wait a minimum of 7 days before entering a treated field.

- Greenhouse: The recommended reentry period is a minimum of 14 days.

Step 5: Cleaning of material and drum disposal

- After application, dilute any remaining product in the tank with water and apply to the treated plot.

- Clean machinery of soil prior to storage.

- Following drip irrigation, flush lines with water. Do not oversaturate the treated soil.

- Treat empty containers as hazardous waste.

- For drums:

- Rinse with clear water and apply remaining product to the treated plot, avoiding ditch and water surface contamination.

- Take drums to a certified collection center.

- For IBC:

- Empty containers as far as possible. Recuperation is assured by container manufacture.

Step 6: Removal of plastic film seal and/or soil aeration

- There is a small risk of residual MITC gas emission.

- Soil aeration two to three weeks (always follow local label requirements) after soil disinfection by rotative tractor device should not be deeper than the disinfected target layer.

Step 7: Cleaning of personal protective equipment (PPE)

- Follow manufacturers’ instructions for cleaning PPE.

- If no instructions exist, use detergent and hot water.

- Discard clothing drenched or heavily contaminated with metam-based product and do not reuse.

- Do not transport contaminated clothing inside a closed vehicle unless stored in a sealed container.

Step 8: Monitoring residual MITC

Checking safety of work and residential environment

A distinction should be made between MITC concentration just above the soil and MITC concentration at worker inhalation height and in the surroundings for bystander and resident exposure. Measurements should be made at different distances downwind from the treated plot.

Measuring devices

- A photoionization detector (PID) is an easy-to-use, quick-response electronic device for this purpose.

- A sealed glass gas reaction tube is also used for detection.

Checking for potential phytotoxicity risk after disinfection

- The typical test to perform is the cress (or lettuce) seed germination test.

- Alternatively, sow or transplant a few of the crops to be installed on the treated area.

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims differ based on government requirements. Use plant protection products safely. Always read the label and product information before use.